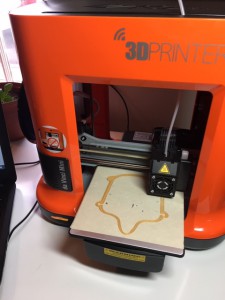

Hartford Public Library has deployed its small fleet of 3D printers into the fight against the spread of coronavirus.

Four of the organization’s six machines were taken from the Downtown Library and placed in the homes of staff members who are working diligently to make mask adaptors for UConn Health. The other two printers will be retrieved from HPL’s neighborhood libraries and pressed into service as well.

The mask adaptor is a plastic frame that fits around the nose and mouth, allowing UConn Health to adapt its current stock of masks to be more effective in preventing the virus.

Keith Petit, property administration manager for the UConn Health office of logistics management, said that they have a stock of masks that were purchased for a previous outbreak which have technically expired. However, the N95 Filters themselves do not expire, just the elastic on them. So there is an opportunity to save the masks.

“Because the elastic gets brittle with age it won’t give a good seal to your face, so they are worthless. By putting an adapter over your face with a new elastic band they become useful again. This is how we were able to repurpose old masks. We also modified the adapter to have spikes, which allows us to use alternate materials like surgical wrap which has filtration qualities similar or exceeding to N95,” Petit wrote in a recent e-mail.

HPL President and CEO Bridget Quinn-Carey knew that other libraries around the country were assisting health care providers by creating masks and other equipment. When UConn Health reached out for assistance, she didn’t hesitate to say yes.

“With the library closed, it feels like we’re not able to be on the front lines as we often are during a crisis — when there is a storm or other disaster libraries are often the ONLY public places open for people to gather, charge devices, get information or supplies. It feels so strange not being open and unable to directly help people — doing this is something we can do to proactively help,” Quinn-Carey said.

Little coaxing was needed to find staff members who were eager to help.

“Our colleagues were just as eager to say yes and get this underway as I was — we have an amazing team. It says so much about them that they were willing to gather and pick up the printers and set them up at their homes — talk about working remotely,” Quinn-Carey said.

The printing process is time consuming. It takes about a half hour to print a single mask. Once printed, librarians will drop the masks off at the Downtown Library, careful to take all necessary social distancing precautions, and the masks will be brought to UConn Health.

Marie Jarry, director of public services, said the library is working through its stock of filament – the tough fiber used in 3D printing – and will make as many masks as possible. She expects that the current allotment of filament will make upward of 100 adaptors.

When the filament is depleted, Jarry said the library will go out and buy more raw material. “We have a good amount in stock and we are going to be purchasing more,” she said.

With 3D printers now pushed into action, Jarry is considering another library resource; its stock of sewing machines. “I am going to see if we have anyone willing to sew the cloth masks that people are asking for,” Jarry said.

The virus is expected to hit its peak in Hartford County sometime in May. The pressure on healthcare providers isn’t expected to let up anytime soon. In the meantime, in this one particular way, Hartford Public Library will be there to help.

“As long as they keep asking, we’ll keep making them,” Jarry said.

- By Steven Scarpa, Manager, Communications and Public Relations

– 30 -

Just thank you for this super story! Keep us posted – it helps! I am usually at the fore in tech things, but an injury sidelined me for some time – where can I learn 3-D printing librarians? you know everything